My fiber week was spent back to what I like doing the most. Making ropes for mecate reins, leashes or lead ropes and of course my fiber of choice is alpaca. But why?

When I got into raising alpacas everyone told me how much better alpaca fiber was for one reason or another and I wanted to do the research and find out if folks were just blowing smoke up my @$$ or not. It turns out there was hardly any research done and I only could find 1 article done by the Yocom-McColl Testing lab, Texas A&M and University of Wyoming entitled “Fiber Characteristics of US Huacaya Alpacas.”

I specifically wanted to learn about fiber strength. I was not interested in crimp, color, diameter, or any other characteristic unless it directly affected the strength of the fiber.

First and foremost; how is strength calculated and what is is the minimum needed for today’s high speed mill industry? Strength is calculated in Newtons/kilotex (N/ktex) and is the force measured in Newtons required to break a staple of given thickness measured in kilotex. Mother Earth exerts 9.8 Newtons(1kg x 9.8m/s2) and kilotex is the thickness in terms of mass per unit length (kg/km).

Today’s milling industry requires fiber with a minimum of 30N/ktex tensile strength for processing.

Wool

Wool fiber has a direct correlation between fiber diameter and staple strength. So much so that Australia research actually has come up with a formula for breeders to follow to improve upon tensile strength. They can use the CVD (Coefficient Variation Standard Deviation) from fiber reports to improve upon N/ktex. Breeding for a CVD of 19% or lower creates a stronger wool fiber. In other words, say your ewe’s mean micron count is 20, breeding to stay within 19% of 20 is ideal for fiber strength. Wool breeders aiming for this CVD, results in producing wool with 30-38 N/ktex.

Huacaya Alpaca Fiber

As it turns out alpaca fiber is extremely strong and has no correlation to color, fiber diameter, or length. It is naturally strong fiber! So much so that further studies on its strength aren’t even bothered with because 90% of fiber tested scored higher than the 30N/ktex required for the milling industry. The mean tensile strength of alpaca is 50N/ktex. The one study I found back in 1997 for Suri show’s their fiber strength to be 44.4N/ktex. I’m now hearing reports that Suri is stronger than Huacaya due to recent breeding practices but I have not been able to find recent research supporting this claim.

One thing when reading through this study that I did notice, is that alpaca fiber strength seems to increase dramatically with animals raised in the Great Lakes and Northeast regions. I’m not sure if it’s the cold weather, snow, or forage that the alpaca fiber seems to like, but animals in these regions score and average of 56.25N/ktex. Alpacas from the central, south and western regions scored an average of 47.26N/ktex. Fiber Diameter does not appear to affect the strength at all over the regions.

| Great Lakes/North East | Central, South and West | % difference | |

| Average Strength N/ktex | 56.25 | 47.26 | 15.98% |

| Average Diameter µm | 29.6 | 27.9 | 5.7 % |

The study does show that alpaca is also nicer than most wools in that the longer the fiber length does not mean courser fiber. In fact it tends to be reversed. The longer the alpaca fiber the finer the micron count and again fiber strength does not appear to be an issue. Long, fine, short or course alpaca scores above the required 30N/ktex every time.

I hope I didn’t bore you too much and I guess to sum everything up; alpaca is STRONG!

So what have I been doing with my superior strength alpaca? Making ropes of course.

here are some photos of the crazy process I go through to make the 6’ braided dog leashes pictured here.

[wp_eStore_fancy3 id=36]

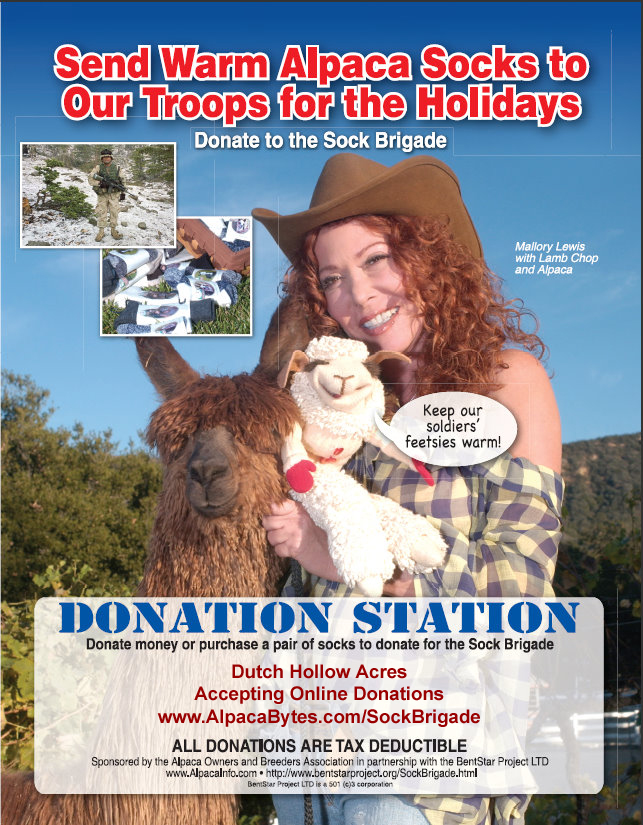

I participate in….